At 4A Fastener, our primary objective is client satisfaction, achieved through the production and delivery of superior-quality, impeccable products, along with competitive pricing and punctual delivery..

Throughout the manufacturing process, close monitoring occurs at every stage—from sourcing raw materials to processing and final product delivery. Advanced data monitoring software and in-line quality checks are employed to ensure rigorous adherence to automotive and industrial standards. Random sampling, as outlined in the sampling plan, is conducted, and components undergo scheduled testing before dispatch to ensure optimal product performance.

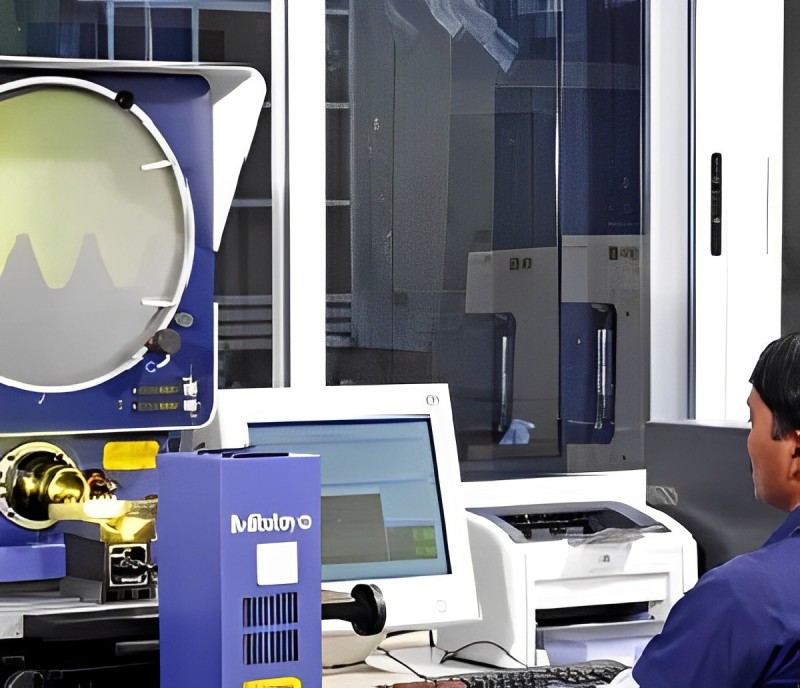

Additionally, our advanced standard room, equipped with state-of-the-art tools like 3D CMM machines and various calibration instruments, plays a pivotal role in ensuring impeccable product quality.

We conduct various testing modules, including metallurgical tests encompassing both Micro and Macro evaluations. Dimensional inspections involve profiling depth, contour measurements, and surface roughness assessments. Additionally, our mechanical tests cover hardness, tensile strength, yield, torque, wedge tests, and others. Finally, endurance tests such as salt spray and coating thickness evaluations are conducted. These rigorous tests are aimed at ensuring that our end products not only meet but exceed customer satisfaction.

All our testing and measuring instruments and equipment are regularly calibrated from NABL accredited sources, ensuring further reliability of the tests performed. We can supply full chemical and mechanical test certificates as per BS EN 10204 3.1 for most of our products.

We aim to get our lab ISO 17025/NABL accredited by the end of the year 2019.

Various testing modules are employed, starting with Metallurgical Testing encompassing both Micro and Macro evaluations. Following that, Dimensional Inspection involves assessing Depth profiles, Contour measurements, and Surface Roughness. Additionally, Mechanical tests cover aspects like Hardness, Tensile strength, Yield, Torque, Wedge testing, among others. Finally, Endurance testing, including assessments for Salt Spray, Coating thickness, and more, aims to ensure that our products not only meet but exceed customer expectations.

Turbo Testing setup is equipped with:

Raw material inspections adhere to the Control Plan. Testing is performed using advanced equipment such as the Vacuum Emission Spectrometer, Metallurgical microscope, UTE (Ultrasonic Testing Equipment), Sand testing laboratory, Hardness Testing machines, and Impact testing machines.

© 4A Fasteners - All Right Reserved

Have an account? Login